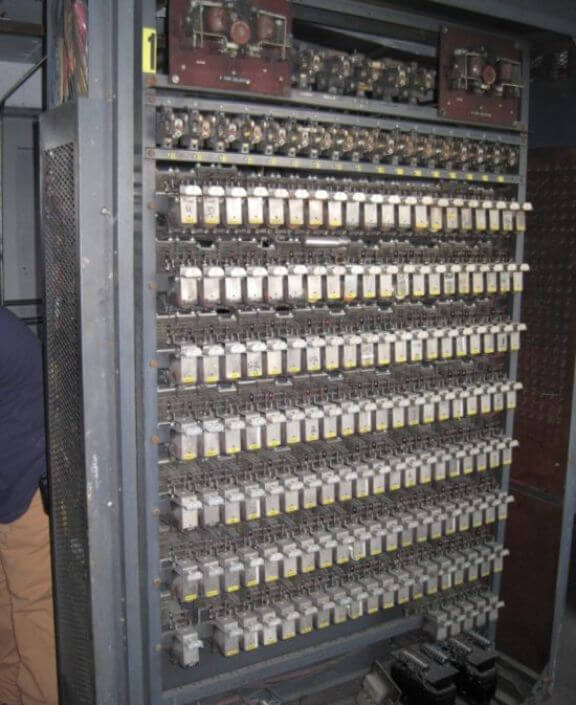

Removal of Obsolete Control Systems

Many control systems and selector systems are outdated and have older components that are now obsolete. Replacement parts for these components are difficult to obtain and can be expensive, which is why these systems should be removed and replaced.

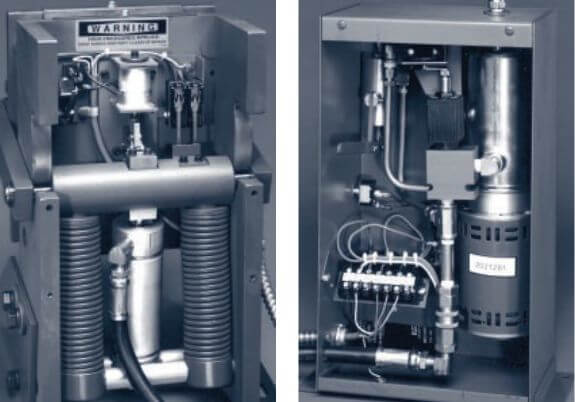

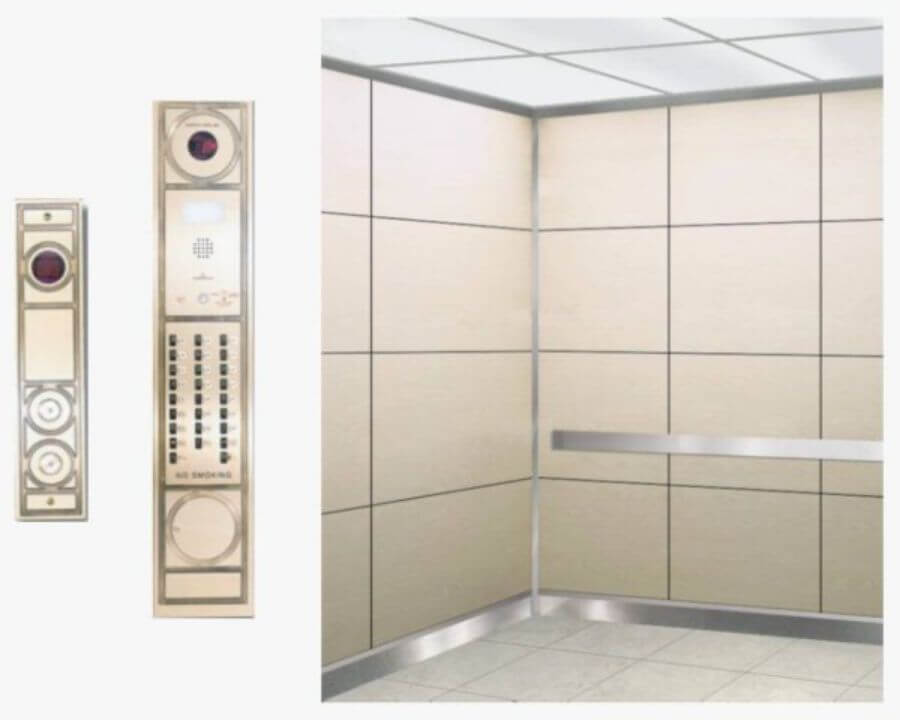

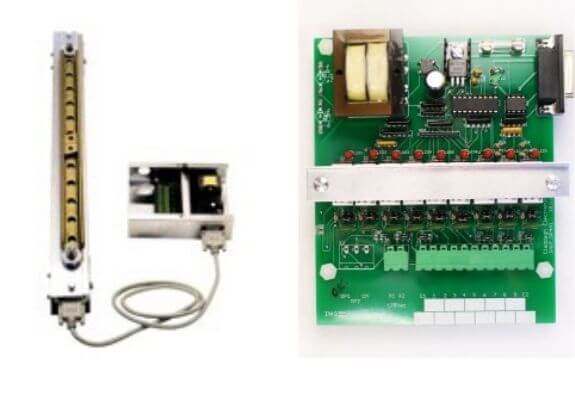

Installation of New Non-Proprietary Elevator Control System

New microprocessor-based intelligent controllers are highly efficient and reliable. This computerized technology drastically reduces the amount of moving electrical contacts, which decreases system malfunctions. The LED display allows for easy troubleshooting and parameter adjustments. Any reputable elevator company can service the system without the need for handheld diagnostic tools or software upgrades, and parts are available the same day.